X-ray Tube Housing Assembly TOSHIBA E7239X

X-ray Tube Housing Assembly TOSHIBA E7239X

This product has been manufactured and developed in agreement with the following laws,directives and design regulations:

◆Council Directive 93/42/EEC of 14 June 1993 concerning medical devices(CE marking).

◆EN ISO 13485:2016 Medical device—Quality management systems—Requirements for regulatory

purposes..

◆EN ISO 14971:2012Medical devices - Application of risk management to medical devices (ISO 14971:2007, Corrected version 2007-10-01)

◆EN ISO15223-1:2012Medical devices——Symbols to used with medical device labels, labeling and information to be supplied Part 1: General requirements

◆International Electrotechnical Commission (IEC),the following standards are considered in particular.

|

Standard Reference |

Titles |

| EN 60601-2-54:2009 | Medical electrical equipment - Part 2-54: Particular requirements for the basic safety and essential performance of X-ray equipment for radiography and radioscopy |

| IEC60526 | High-voltage cable plug and socket connections for medical X-ray equipment |

| IEC 60522:1999 | Determination of the permanent filtration of X-ray tube assemblies |

| IEC 60613-2010 | Electrical, thermal and loading characteristics of rotating anode X-ray tubes for medical diagnosis |

| IEC60601-1:2006 | Medical electrical equipment - Part 1: General requirements for basic safety and essential performance |

| IEC 60601-1-3:2008 | Medical electrical equipment - Part 1-3: General requirements for basic safety and essential performance - Collateral Standard: Radiation protection in diagnostic X-ray equipment |

| IEC60601-2-28:2010 | Medical electrical equipment - Part 2-28: Particular requirements for the basic safety and essential performance of X-ray tube assemblies for medical diagnosis |

| IEC 60336-2005 | Medical electrical equipment-X-ray tube assemblies for medical diagnosis-Characteristics of focal spots |

●The designation is composed as follows:

|

MWHX7010 |

Tube |

A |

High voltage socket with 90 degree direction |

|

MWTX70-1.0/2.0-125 |

B |

High voltage socket with 270 degree direction |

|

Property |

Specification |

Standard |

|

|

Nominal input power(s) of the anode |

F 1 |

F 2 |

IEC 60613 |

|

21kW(50/60Hz) |

42.5kW(50/60Hz) |

||

|

Anode heat storage capacity |

100 kJ ( 140kHU) |

IEC 60613 |

|

| Maximum cooling capacity of the anode |

475W |

||

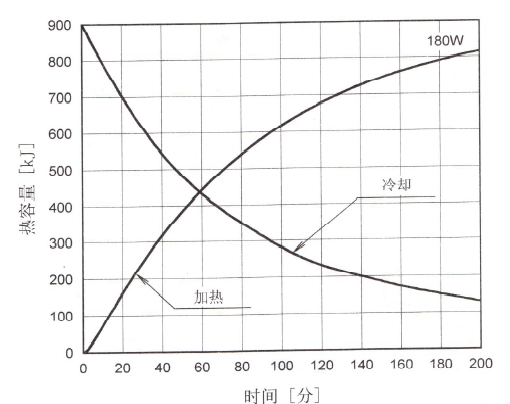

| Heat storage capacity |

900kJ |

||

| Max. continuous heat dissipation without Air-circular |

180W |

||

| Anode materialAnode top coating material |

Rhenium-Tungsten-TZM(RTM) Rhenium-Tungsten-(RT) |

||

| Target angle (Ref: reference axis) |

16 ° |

IEC 60788 |

|

| X-ray tube assembly inherent filtration |

1.5 mm Al / 75kV |

IEC 60601-1-3 |

|

|

Focal spot nominal value(s) |

F1(small focus) |

F2(large focus) |

IEC 60336 |

|

1.0 |

2.0 |

||

| X-ray tube nominal voltageRadiographic

Fluoroscopic |

125kV 100kV |

IEC 60613 |

|

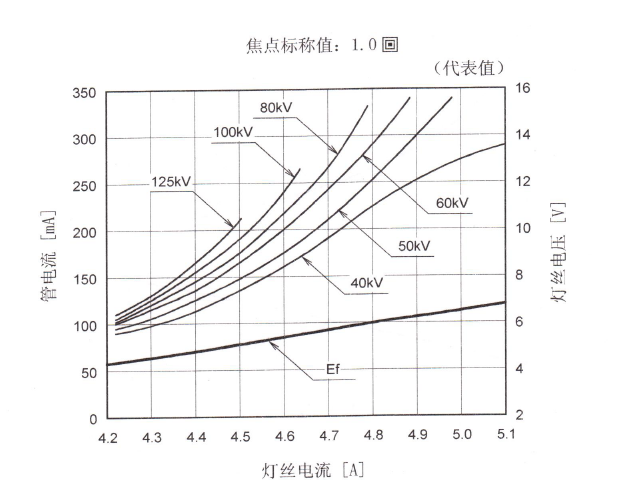

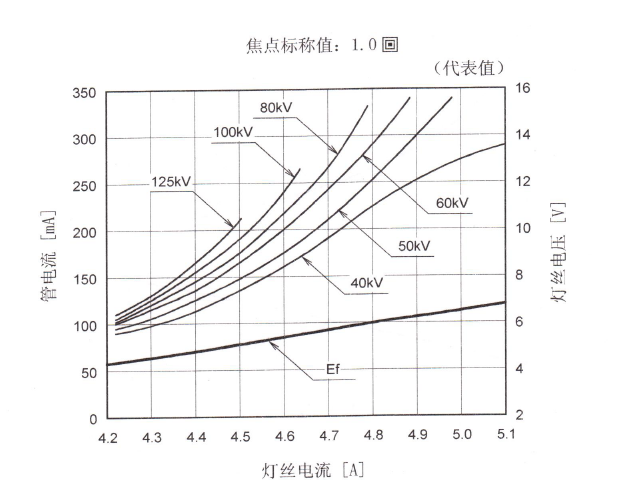

| Data on cathode heating

Max. current Max voltage |

≈ /AC, < 20 kHz |

||

|

F1 |

F 2 |

||

|

5.1A ≈5.8~7.8V |

5.1 A ≈7.7~10.4 V |

||

| Leakage radiation at 150 kV / 3mA in 1m distance |

≤ 1.0mGy/h |

IEC60601-1-3 |

|

|

Maximum radiation field |

573×573mm at SID 1m |

||

| X-ray tube assembly weight |

Approx. 18 kg |

||

|

Limits |

Operation Limits |

Transport and Storage Limits |

|

Ambient temperature |

From 10℃to 40℃ |

From- 20℃to 70℃ |

|

Relative humidity |

≤75% |

≤93% |

|

Barometric pressure |

From 70kPa to 106kPa |

From 70kPa to 106kPa |

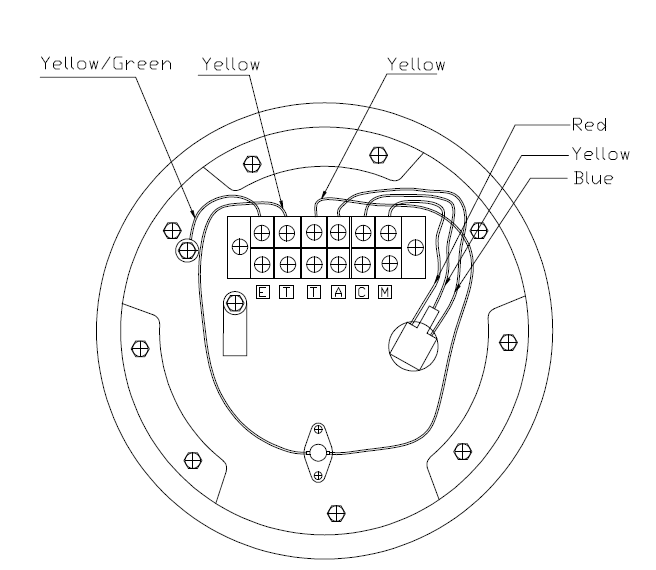

1-phase stator

| Test point |

C-M |

C-A |

| Winding resistance |

≈18.0…22.0Ω |

≈45.0…55.0Ω |

| Max.permissible operating voltage(run-up) |

230V±10% |

|

| Recommend operating voltage(run-up) |

160V±10% |

|

| Braking voltage |

70VDC |

|

| Run-on voltage in exposure |

80Vrms |

|

| Run-on voltage in fluoroscopy |

20V-40Vrms |

|

| Run-up time(depending on starter system) |

1.2s |

|

Warning to interface with X-ray Generator

1.Housing Rupture

Never input over rated power to X-ray tube assembly

If the input power exceeds the tube's specifications, it may cause the anode to overheat, the tube glass to shatter, and ultimately may cause serious problems due to overvoltage caused by vaporization of oil within the housing assembly. In a critical situation where the housing ruptures due to overload, the safety thermal switch may not be able to protect the X-ray tube, even if it is operating.

*Housing sealing parts rupture.

*Human injury including burns due to hot oil escape.

*Fire accident due to flaming anode target.

The X- ray generator should have a protective function which manages input power to be within tube specification.

2.Electric Shock

To avoid the risk of electric shock ,this equipment must only be connected to a supply with protective earth.

3.No modification of this equipment is allowed!!

Caution to interface with X-ray Generator

1.Over Rating

Too much energy in a single shot may cause X-ray tube assembly failure.It is important to carefully review the technical data sheet and follow the specified instructions to avoid damage.

2.Permanent Filtration

Legal regulations specify the total amount of filtration required and the minimum distance between the X-ray focus point and the human body.

They should be complied with the regulation.

3.Safety Thermal Switch

X-ray tube assembly has safety thermal switch to prohibit further input power when the tube housing reaches to the temperature(80℃) of switch-open.

The switch is not recommended connecting stator coil in series circuit.

Even if the switch works ,never turn the system power off. The cooling unit should be activated if used with the system.

4.Unexpected Malfunction

X-ray tube assemblies can malfunction or fail unexpectedly, creating the risk of serious problems. It is important to have a contingency plan in place to prevent and resolve any problems that may arise from this risk.

5.New Application

If you plan to use this product in a new application not specified in this document, or if you plan to use a different type of X-ray generator, please contact us to confirm compatibility and availability.

1 .X-ray Radiation protection

This product fulfills the requirements of IEC 60601-1-3.

This X-ray tube assembly emits X-ray radiation in operation.Only correspondingly qualified and trained personnel are therefore allowed to operate the X-ray tube assembly.

Relevant physiologic effects may cause harm to patient,system manufacture should take proper protection to avoid ionization radiation.

2.Dielectric 0il

X-ray tube assembly has dielectric 0il contained for high voltage stability. As it is poisonous for human health,if it is exposed to the non-restricted area,it should be disposed as following to the local regulation.

3 .Operation Atmosphere

X-ray tube assembly is not allowed to be used in the atmosphere of flammable or corrosive gas·

4.Adjust the Tube Current

Depending on the operating conditions,the filament characteristics might be changed.

This change might Iead to the over rate exposure to X-ray tube assembly.

To prevent the X-ray tube assembly from being damaged,adjust the tube current regularly.

Besides when the X-ray tube has arcing Problem in a long time use,adjustment of the tube current is required.

5.X-ray Tube Housing Temperature

Do not touch on X- ray tube housing surface just after operation due to high temperature.

Stay X-ray tube to be cooled.

6 .Operating limits

Prior to usage,please confirm the environmental condition is within the operating Iimits.

7 .Any Malfunction

P1ease contact to SAILRAY immediately,if any malfunction of the X-ray tube assembly is noticed.

8.Disposal

The X-ray tube assembly as well as the tube contain materials such as oil and heavy metals for which environmentally friendly and proper disposal in accordance with the valid national legal regulations must be assured.Disposal as domestic or industrial refuse is forbidden.The manufacturer possesses the required technical knowledge and will takes the X-ray tube assembly back for disposal.

Please contact customer service for this purpose.

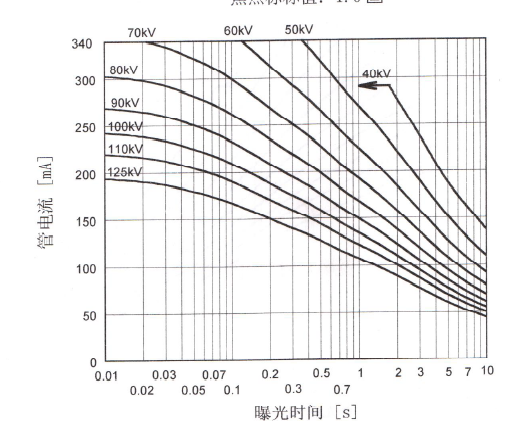

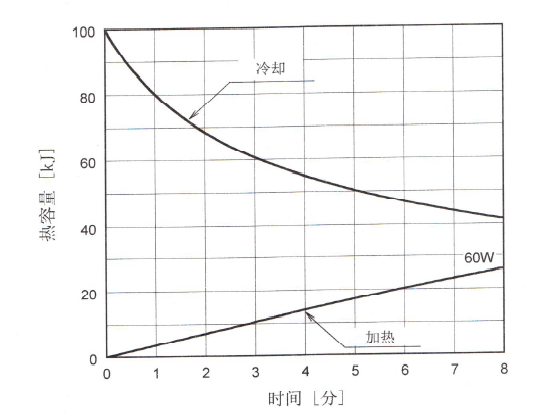

If(A) Small Focal Spot

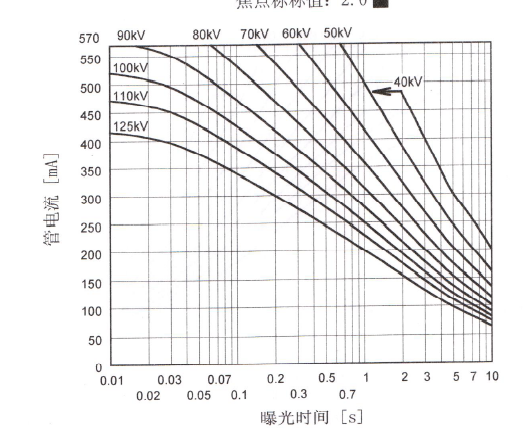

If(A) Large Focal Spot

Conditions:Tube Voltage Three-Phase

Stator Power Frequency 50Hz/60Hz

IEC60613

Housing Thermal Characteristics

SRMWHX7010A

SRMWHX7010B

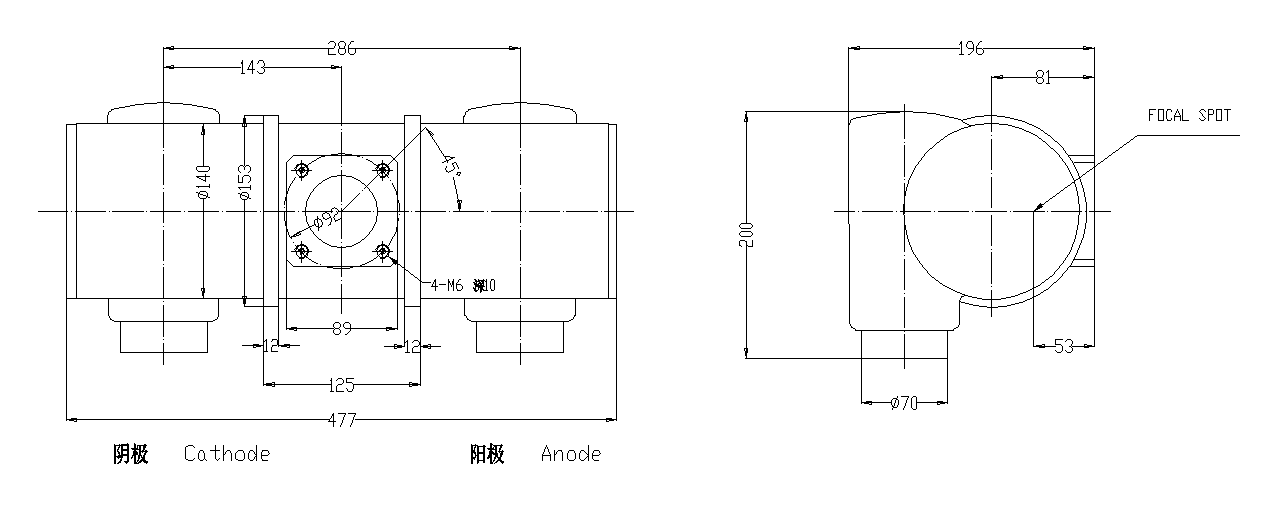

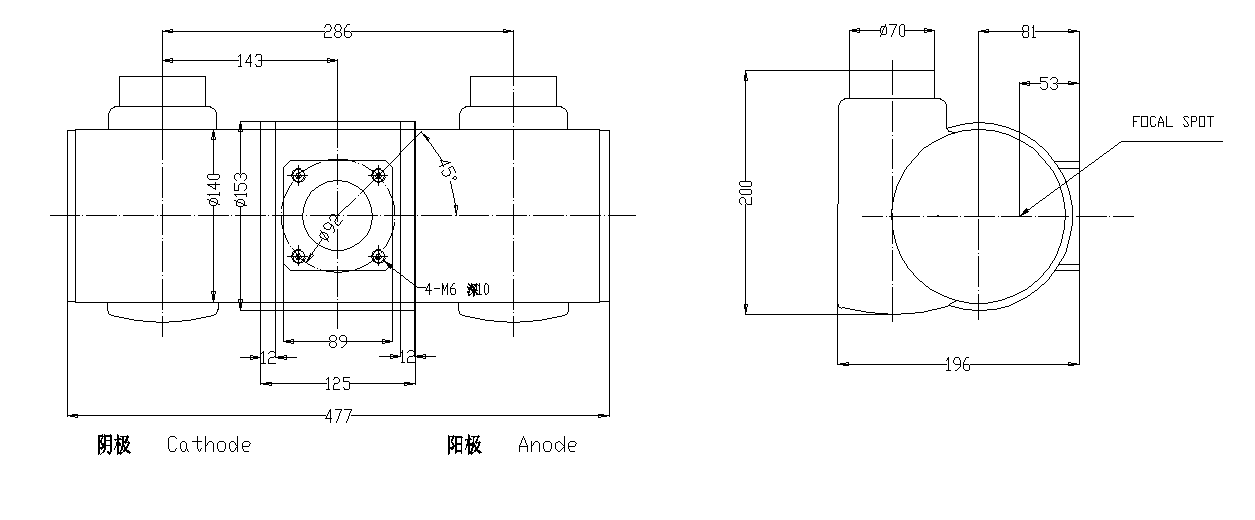

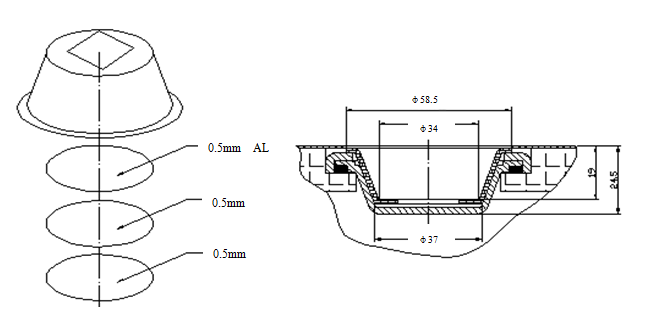

Filter Assembly And Cross Section of Port

Rotor Connector Wiring

Minimum Order Quantity: 1pc

Price: Negotiation

Packaging Details: 100pcs per carton or customized according to the quantity

Delivery Time: 1~2 weeks according to the quantity

Payment Terms: 100% T/T in advance or WESTERN UNION

Supply Ability: 1000pcs/ month