OEM High Quality Induction Motor X Ray Tube Manufacturers - Dental X-ray Tube CEI Ox_70-m – Sailray

OEM High Quality Induction Motor X Ray Tube Manufacturers - Dental X-ray Tube CEI Ox_70-m – Sailray

OEM High Quality Induction Motor X Ray Tube Manufacturers - Dental X-ray Tube CEI Ox_70-m – Sailray Detail:

KL1-0.8-70 Stationary anode X-Ray Tube is especially designed for intra-oral dental x-ray unit and available for a nominal tube voltage with self-rectified circuit.

KL1-0.8-70 tube has one focus.

The integrated high quality tube with glass design has one super imposed focal spot and a reinforced anode.

The high anode heat storage capacity ensures a wide range of applications for intra-oral dental application. A special designed anode enables an elevated heat dissipation rate which leads to a higher patient throughput and a longer product life. A constant high dose yield during the entire tube life is ensured by the high density tungsten target. Ease of integration into system products is facilitated by extensive technical support.

KL1-0.8-70 Stationary anode X-Ray Tube is especially designed for intra-oral dental x-ray unit and available for a nominal tube voltage with self-rectified circuit.

| Nominal Tube Voltage | 70kV |

| Nominal Inverse Voltage | 85kV |

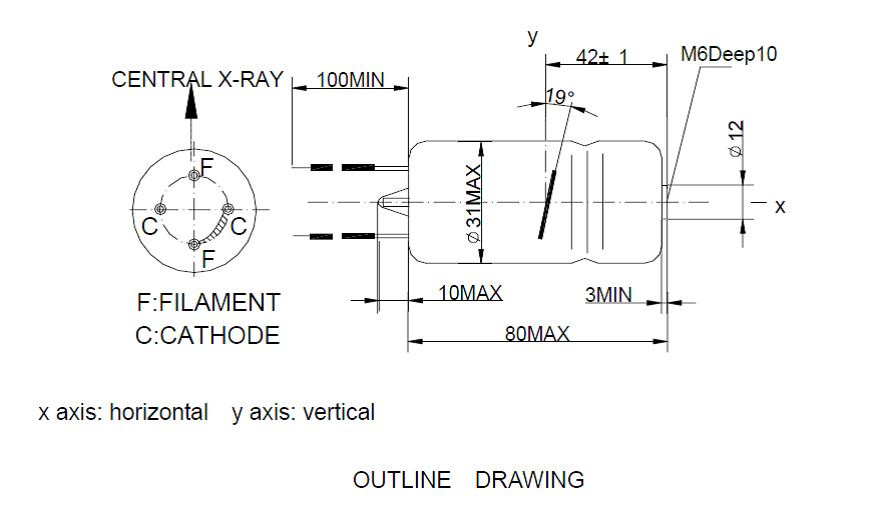

| Nominal Focal Spot | 0.8 (IEC60336/1993) |

| Max. Anode Heat content | 7000J |

| Max. Current Continuous Service | 2mA x 70kV |

| Max. Anode Cooling Rate | 140W |

| Target Angle | 19° |

| Filament Characteristics | 1.8 – 2.2A, 2.4 – 3.3V |

| Permanent Filtration | Min. 0.6mm Al / 50 kV(IEC60522/1999) |

| Target Material | Tungsten |

| Nominal Anode Input Power | 840W |

Elevated anode heat storage capacity and cooling

Constant high dose yield

Excellent lifetime

Prior to usage, season the tube in accordance with the seasoning schedule given below until the required tube voltage is attained. Example given – needs to revise by the manufacturer and specified in the data sheet of the part:

Initial incoming seasoning and seasoning schedule for idle period (more than6months)Circuit:

When the tube current is unstable in seasoning, immediately switch off the tube voltage and after an interval of 5 minutes or more, increase the tube voltage gradually from the low voltage while making sure that the tube current is stable. The withstand voltage performance of the tube unit will be lowered as the exposure time and the number of operation increase. Stain-like impact traces might appear on the x-ray tube target surface by slight discharge in the course of the seasoning. These phenomena are one process to recover the withstanding voltage performance at that time. Therefore, if it is in stable operation at the maximum tube voltage of seasoning subsequent to them, the tube unit can be used without any interference to its electrical performance which in use.

Cautions

Read the cautions before using the tube

X-ray tube will emit X –ray when it is energized with high voltage, Special knowledge should be required and cautions need to be taken when handling it。

1. Only a qualified specialist with X-Ray tube knowledge should assemble, maintain and remove the tube。

2. Sufficient care should be taken to avoid strong impact and vibration to the tube because it is made of fragile glass。

3. Radiation protection of the tube unit must be sufficiently taken。

4. The minimum sorce-skin distance (SSD) and the minimum filtration should match the regulation and meet the standard。

5. The system should have proper overload protection circuit, the tube may be damaged due to only one overload operation。

6. When any abnormalities are found during operation, immediately switch off the power supply and contact the service engineer。

7. if the tube is with a lead shield, to dispose of lead shield must meet government regulations。

Product detail pictures:

Related Product Guide:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for OEM High Quality Induction Motor X Ray Tube Manufacturers - Dental X-ray Tube CEI Ox_70-m – Sailray , The product will supply to all over the world, such as: Amman, Germany, Malta, With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

Minimum Order Quantity: 1pc

Price: Negotiation

Packaging Details: 100pcs per carton or customized according to the quantity

Delivery Time: 1~2 weeks according to the quantity

Payment Terms: 100% T/T in advance or WESTERN UNION

Supply Ability: 1000pcs/ month

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.